From H2S to Success: The Tucson Boulevard Diversion Structure

Revitalizing Wastewater Management in Tucson

Written by: Crystal Faucett and Keith Faucett, PE

In northern Tucson, just steps away from the popular Rio Vista Natural Resource Park, nearly 25 million gallons of wastewater flow through the Tucson Boulevard Diversion Structure each day. This key structure helps Pima County Wastewater Reclamation manage and balance flows between two major interceptor sewers, allowing the County to accommodate growth and maintenance.

After decades of use and modifications, the existing diversion structure became an odorous, corroded, and dangerous facility to manage. Park-goers and residents in the area complained about the odor, which was more than a nuisance; it was a symptom of the excessive hydrogen sulfide (H2S) gas produced within the structure, where the corrosive, noxious gas wreaked havoc. The corroded diversion gates became non-functional, and entering the structure to adjust flows required extensive safety precautions. Addressing these issues—odor, corrosion, and safety—was a top priority for the County.

After evaluating the system, Dibble recommended removal and designed a replacement system. The new custom system required close coordination among Dibble, the County, and Hunter Contracting Co. (the construction manager at risk) throughout design and construction. Working together, the project team provided an innovative long-term solution for this complex situation.

Demolishing the existing structure

(photo by Hunter Contracting Co.)

Placing the lid on the new custom structure

(photo by Hunter Contracting Co.)

ADDRESSING ISSUES THROUGH CAREFUL DESIGN

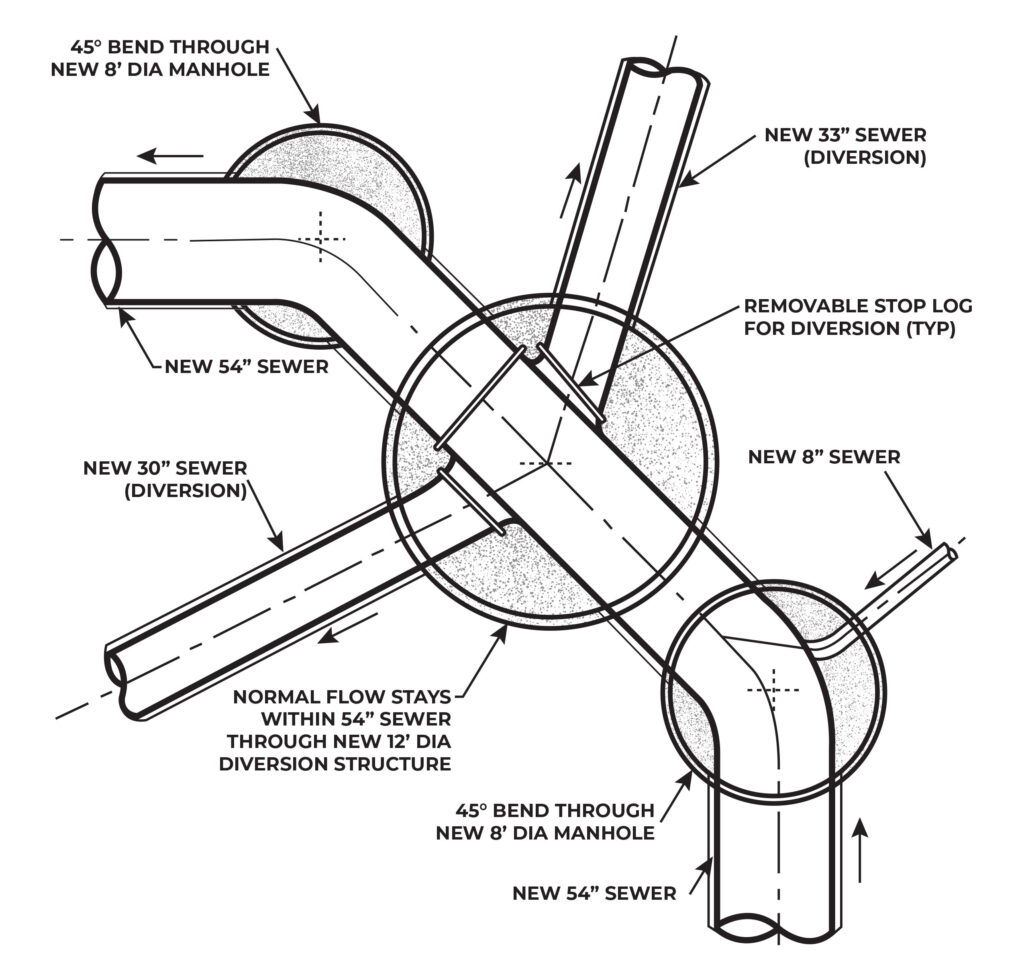

In the existing structure, multiple flow activities occurred in a single confined space—bends (including a tight 90-degree bend), expansions, contractions, and merging flows—all at high flow rates. This configuration created a roaring turbulent mix that produced excessive amounts of hazardous H2S gas.

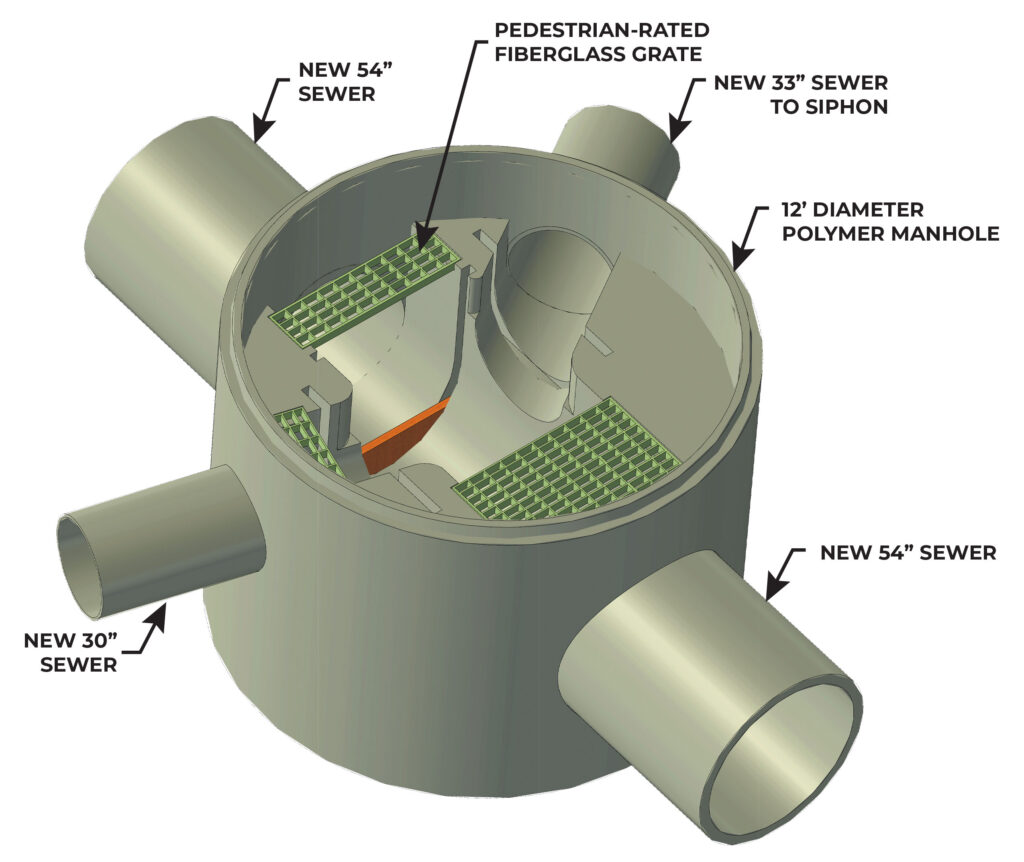

To reduce turbulence, Dibble’s design separated flow activities into three separate structures. The flow in the 12-foot-diameter center structure is designed to typically stay below the inverts of the two connecting diversions, thus reducing energy losses, turbulence, and H2S gas production. The new system is constructed of innovative non-corrosive materials including pre-cast polymer concrete and fiberglass, which will significantly extend the service life of the system.

Effective communication was crucial during design, especially for the one-of-a-kind center structure. After developing a 3D model of the structure, Dibble 3D-printed a physical model and brought it to meetings. This allowed the team to examine the model physically, visualize how the structure would work, and discuss constructability. Dibble also used the 3D model to develop plan details and collaborate with Armorock to ensure the design was compatible with current precast polymer manufacturing capabilities. This helped ensure that the custom structure met the design intent and the County’s needs.

IMPROVING SAFETY AND QUALITY OF LIFE

The diversion structure is located in a quiet community that includes homes, stables, and Rio Vista Natural Resource Park. A short walk from the diversion structure is the Rillito River, along with “The Loop,” which was recently named the number one bike path in America by USA Today. This area, known for its outdoor appeal, was burdened with odors produced by the aging diversion structure. While the project was in design, this significant issue prompted the local news to produce a story about the “fierce fragrance.” In addition to causing odor issues, the excessive H2S gas in the existing structure posed a potential safety hazard for operations and maintenance personnel. Entering the structure for maintenance required a confined space entry, which involved significant coordination, ventilation, and monitoring.

Dibble’s design mitigates odors and improves safety by reducing turbulence and the associated H2S gas. The new structure is also completely below ground, with stop gates accessible through an access hatch. Operating the stop gates no longer requires a confined space entry, and the new structure is safely and conveniently maintainable. By mitigating odors and removing the unsightly above-ground structure, this project allows the community to better enjoy the tranquil environment.

OVERCOMING CONSTRUCTION CHALLENGES

As part of the project, Hunter Contracting Co. removed and replaced 1,224 linear feet of 54-inch sewer. Sandy soils led to trench cave-ins, which threatened to shift trench boxes and risked exposing an existing 36-inch concrete cylinder pipe (CCP) reclaimed water main. Aging CCP is often fragile, and simply exposing the pipe could cause it to break and flood the trench with thousands of gallons of water. Hunter’s crews worked carefully to protect the existing water main; this was especially challenging where the existing sewer meandered out of alignment, closer than expected to the 36-inch CCP. To resolve this issue, Hunter removed the existing sewer to the next upstream manhole and modified the manhole to allow for a smooth connection.

Installing the new system required extensive wastewater bypass pumping, which can be quite costly. Through close coordination among Hunter Contracting Co., Dibble, the County, and the Arizona Department of Environmental Quality, the project secured discharge authorization quickly, which minimized the bypass pumping duration and cost and kept the project on time and budget.

When a large-diameter coupling was unavailable due to supply chain issues, the team developed a custom fiber-reinforced polymer (FRP) internal joint to connect the new structure to the existing pipe. Dibble’s expertise in FRP design and inspection and Hunter’s experience in FRP installation made this approach a success.

Nearby high-voltage power lines were another challenge. With the extreme summer heat, Tucson Electric Power needed to keep these crucial lines energized during the day, which made it dangerous to use a crane to set the structures. To overcome this, the team worked with equipment experts to use a 75-ton excavator instead. This resulted in substantial savings with no interruption to the power grid.

“This project completely removed the badly corroded above-ground single structure and replaced it with a corrosion-resistant polymer concrete structure and a fiberglass board system…with adjacent inlet and outlet manholes… The confined space safety concerns were eliminated with the new arrangement and the H2S related corrosion and odors were greatly reduced…due to the better hydraulic arrangement of the structures.”

– Jaime Rivera, Deputy Director at Pima County Wastewater Reclamation

AN AWARD-WINNING PROJECT

From the initial study phase to placing the lid on the final structure, the team worked together to make this project a success that has earned national recognition. Thoughtful engineering and non-corrosive materials provide long-term reliability and reduced lifecycle costs for this critical infrastructure. The team’s hard work and commitment led to a unique project completed on time and within budget, with minimal inconvenience to residents and businesses. The new system addresses each of the County’s goals for the project—mitigating odor, avoiding corrosion, and improving safety. Now the County and the community can breathe easily, and the new Tucson Boulevard Diversion Structure can provide value for decades to come.

The video below shows Representative Juan Ciscomani from Arizona’s 6th congressional district recognizing the Tucson Boulevard Diversion Structure project.

This Case Study PDF

Project Details

Project

Tucson Diversion Structure

Location

Tucson, AZ

Market

Tucson Water/Wastewater

Owner

Pima County

Civil Engineer

Dibble

General Contractor

Hunter Contracting

Delivery Method

Construction Manager at Risk