AWT-MF to RO 36-Inch Pipe Repair

REHABILITATING A DETERIORATED PIPE USING FRP

The City of Scottsdale discovered 300 linear feet of deteriorating 36-inch mortar-lined ductile iron pipe (DIP) located within the city’s Water Campus. The sole purpose of this pipe is to convey cleaned wastewater from the microfiltration (MF) building to the reverse osmosis (RO) building.

Dibble provided structural engineering services including structural assessment, design, construction administration, and special inspection for the fiber reinforced polymer (FRP) rehabilitation of the existing deteriorated pipe.

Environmental considerations were required during project construction due to the FRP rehabilitation technique’s dependency with humidity levels. The Dibble team was onsite daily to ensure the pipe surface was prepared adequately to receive the FRP. Dibble also verified that load testing on the material substrate was sufficient to ensure a proper bond between the pipe and the FRP. The team ensured effective schedule maintenance due to water supply commitments to the city’s customers. A maintenance of plant operations (MOPO) plan was prepared to coordinate the facility shutdown and startup operations.

Details

Client

City of Scottsdale

Location

Scottsdale, AZ

Scope

$109K (design and CA&I)

Construction Cost

$436K

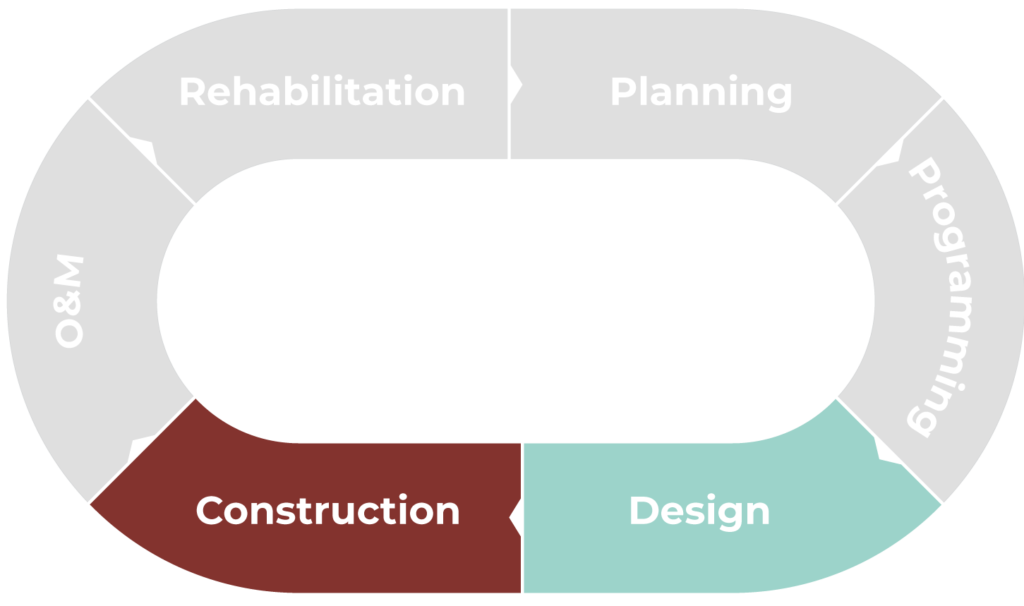

Project Lifecycle