Butler Influent Wet Well Channel Rehabilitation

REHABILITATING CONCRETE WALLS USING PRECAST COMPOSITE PANELS

The City of Peoria needed to rehabilitate the inlet equalization wet well channel of the Butler Influent Pump Station (IPS). The Butler IPS receives sanitary sewer flow from a single 42-inch-diameter pipe from the west into a single equalization basin containing two outlet channels currently equipped with manually operated slide isolation gates. The existing protective coating installed on the wet well’s concrete wall was failing and peeling from the surface due to a high concentration of hydrogen sulfide (H2S) gas, exposing the concrete to the corrosive environment present within the channel.

Dibble prepared an assessment analysis to evaluate and compare repair alternatives to restore the concrete walls to their original dimensions and to prevent further degradation. The Dibble team performed a lifecycle cost analysis to evaluate each rehabilitation alternative’s comparative costs over the wet well’s entire service life. Based on the lifecycle cost analysis, Dibble recommended using SEIS composite panels to repair the concrete walls of the wet well.

Dibble also provided construction administration and structural special inspection for this rehabilitation project. To keep the Butler Water Reclamation Facility operational during construction, an extensive sewer bypass pumping plan was used. Dibble provided close coordination between the contractor and City of Peoria.

Details

Client

City of Peoria

Location

Peoria, AZ

Scope

$259K (design and CA&I)

Construction Cost

$537K

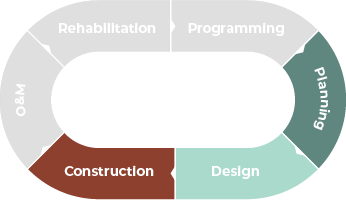

Project Lifecycle