PVC-Lined Sewer Rehabilitation

REHABILITATING DETACHED LINERS IN SANITARY SEWER PIPES USING FRP

Since 2008, Dibble has provided condition assessment and design to rehabilitate sanitary sewer pipelines and repair PVC-lined and epoxy-coating concrete manhole/junction structures for the City of Phoenix. For the 2017 contract, Dibble is rehabilitating approximately 41,000 linear feet of sanitary sewer pipe (approximately 69 segments) ranging from 30 to 60 inches in diameter and approximately 188 access sanitary sewer manholes. Dibble developed technical specifications and design drawings to perform interior T-lock liner repairs or cured-in-place pipe (CIIPP) lining based on available budgets.

During the assessment phase, a prevalent defect found in the pipes was a section of detached liner. In those instances, the host PVC pipe had received CIPP lining during a previous rehabilitation effort and the CIPP liner had shrunk behind the manhole wall. Dibble designed fiber reinforced polymer (FRP) pipe repair along three segments that had experienced detachment, which included Segment 52 (54-inch pipe diameter), Segment 58 (36-inch pipe diameter), and Segment 72 (36-inch pipe diameter).

Dibble designed the FRP wrap to extend between the CIPP liner and the manhole wall to cover the area that was experiencing detachment and to provide strength to that section. The Dibble team was onsite during installation and testing and performed a special structural inspection of the FRP composite system.

Details

Client

City of Phoenix

Location

Phoenix, AZ

Scope

$5.5M (design and CA&I)

Construction Cost

$42.1M

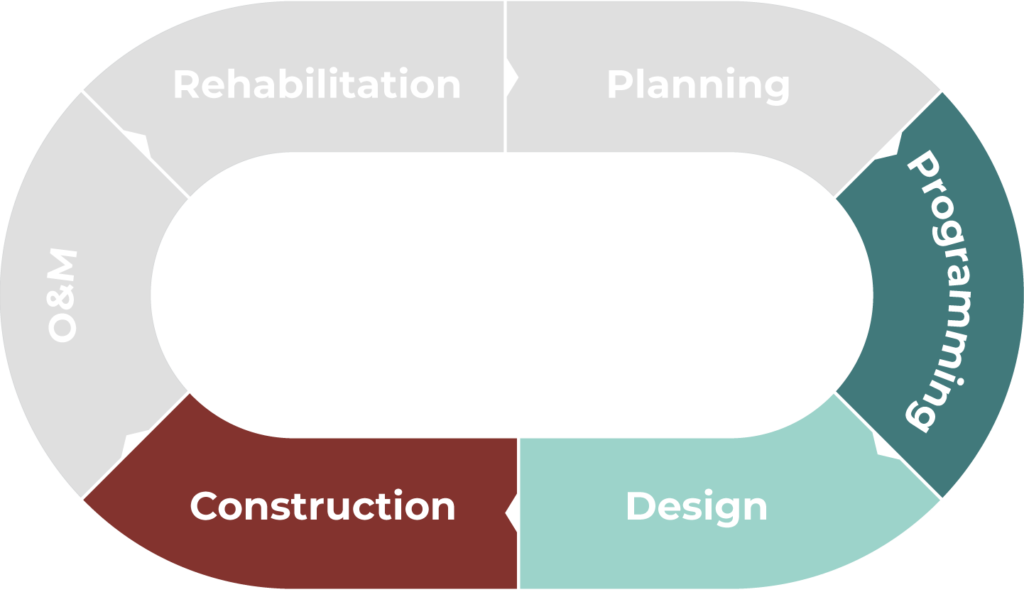

Project Lifecycle